Distilled spirits

Distilled spirits bottles can have many different shapes and sizes, though there are standards in the industry.

This also applies to caps and closures along with the capping & sealing methods used in the industry.

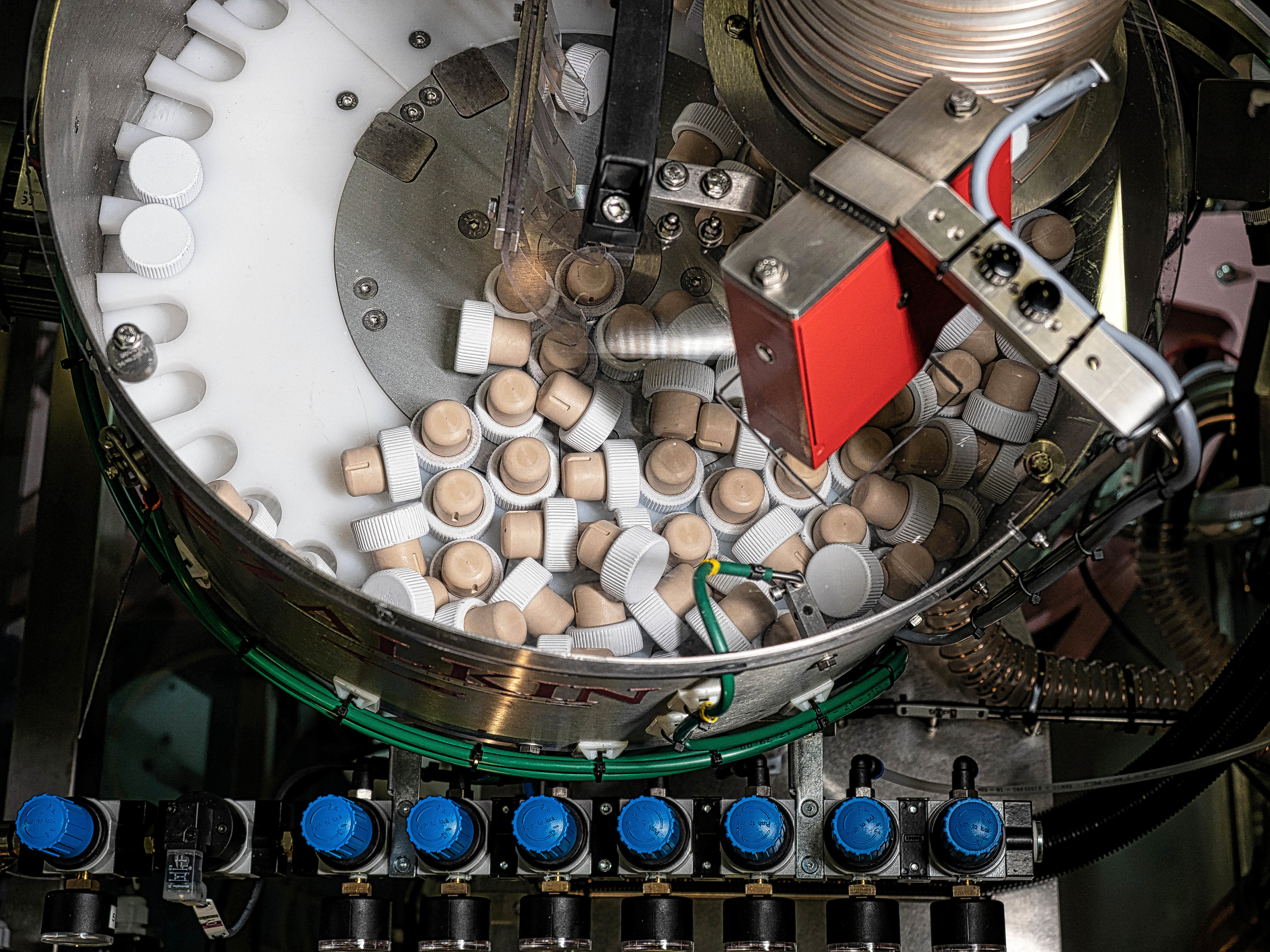

Zalkin has offered innovations to the global capping industry for years. With over 1,700 cappers manufactured for the spirits industry, Zalkin continues to further develop its capping machinery to meet the unique requirements of premium spirits products at locations across Europe, China, South America, the Caribbean, and North America.

Spirits producers are progressively seeking greater visual impact for their brands, often choosing to utilize distinctive materials, shapes or features for closures to set their product apart from the competition and provide the upmost quality image and impression for their brand. All closures require proper handling with specialty closures such as those with a unique shape, high-gloss finish, embossed features, or those made of glass, requiring more sensitive handling and application.

Zalkin continually address the needs to ensure precise and gentle handling of such closures to prevent even minor visual damage and provides technical solutions to reduce or even remove contact between caps:

Cap feeding

Closures loaded into a bulk feeder bin for transport to the cap feeder or cap orienter to supply the capping heads of the capper. Closures can be loaded manually or utilizing robotics for fully automated operation.

Closure orienting

These cappers are often equipped with cap orienters and available in a variety of configurations to accommodate a wide range of closure types.

Cap handling

Cap changeovers may include a combination of quick release cap chutes or cap chute sections. Automated chute positioning allows proper alignment with different cap feed sources.

Bottle handling

Bottle handling equipment is of quick release design requiring no tools for changeover. Format changeover may include bottle neck support and guides to ensure precise alignment of bottles for accurate closure application.