ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreFreestanding Rotary Cappers

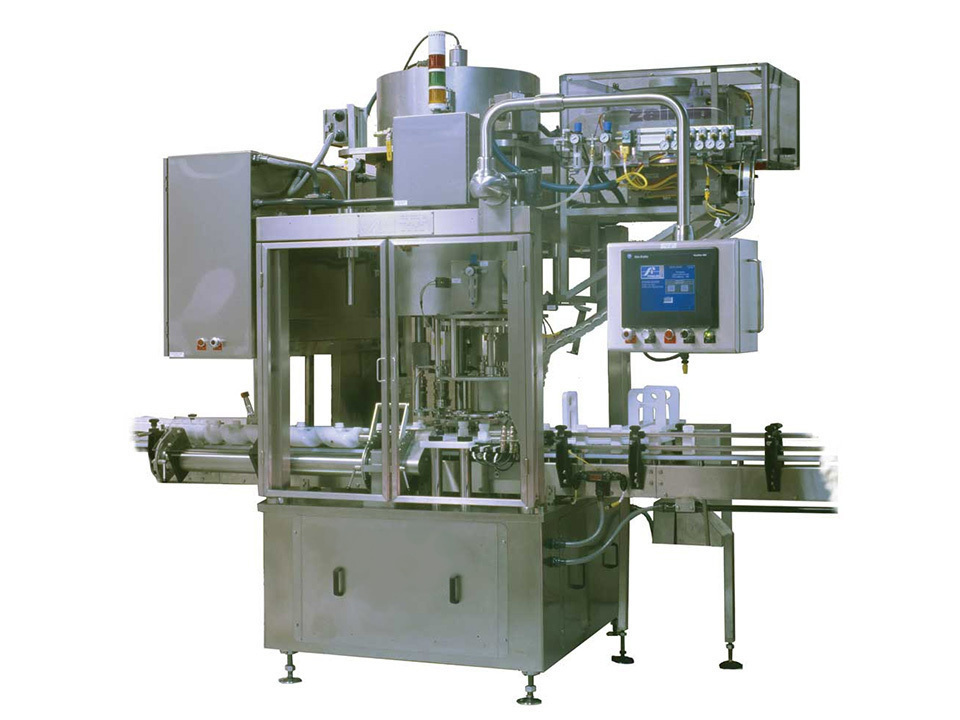

Zalkin freestanding rotary cappers are known worldwide for their reliable and repeatable performance and their durability in even the most demanding production environments.

Zalkin freestanding rotary cappers are available for the following applications:

- Screw-on closures, for plastic screw caps

- Roll-on closures, for aluminum ROPP (Roll On Pilfter Proof) caps

- Push-in (push on) closures, for T-corks, stoppers, and plugs

- Snap-on closures, for snap-caps

- Screw-on + roll-on, for aluminum TOPP (Torque On Pilfer Proof) caps

- Insert + close, for pumps and triggers

- Screw-off, for decapping screw-on closures on returnable bottles

Zalkin freestanding rotary capper highlights:

- Multiple mid to high speed models and options accommodate a wide range of output up to 60,000 bph

- 3 to 24 capping heads

- Five standard pitch diameters: 300, 360, 480, 640 & 720 mm PCD

- Closure diameters from 18 mm to 120 mm

- Neck handling for light weight and hot filled or flood filled containers that can’t be squeezed during capping

- Fast, tool-less capping head changeover

- Stainless steel construction

- Custom pitch diameter configurations are available

- Multi-turret configurations on the same base are available

Zalkin’s range of capping technologies and capper configurations is unmatched in the industry.

Let us design and configure a perfect solution for your application.

Get in touch with a Zalkin representative near you for more information about Zalkin capping systems and equipment.

Zalkin freestanding rotary screw-on cappers use Zalkin’s proven pick and place technology to apply plastic screw caps to containers at speeds up to 1,000 cpm (60,000 cph).

Zalkin freestanding rotary roll-on cappers use Zalkin’s proven capping head technology to apply aluminum closures to glass and metal bottles at speeds up to 900 cpm (54,000 cph).

Zalkin freestanding rotary push-in (push on) and snap-on cappers use Zalkin’s proven pick and place technology to apply a wide range of cap styles and geometries to containers at speeds up to 900 cpm (54,000 cph).

Zalkin freestanding rotary screw-on + roll-on cappers use Zalkin’s proven capping head technology to apply TOPP aluminum closures to glass bottles at speeds up to 500 cpm (30,000 cph).

Zalkin freestanding insert + close cappers apply pump and trigger spray closures at speeds up to 300 cpm (18,000 cph).